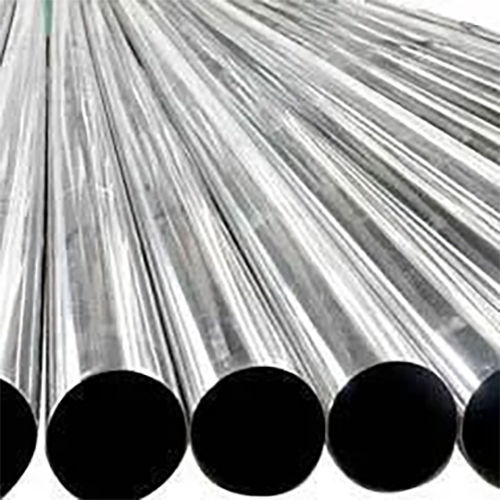

SS PIPES

SS PIPES Specification

- End Protector

- Plastic Caps

- Section Shape

- Round

- Connection

- Welded

- Surface Finish

- Polished

- Application

- Construction, Industrial, Plumbing, Food Processing

- Tolerance

- 1%

- Material

- Stainless Steel

- Feature

- Corrosion Resistance, High Strength, Durable

- Product Type

- Pipe

- Thickness

- 0.5 mm - 10 mm

- Type

- Seamless / Welded

- Shape

- Round

- Technique

- Cold Rolled

- Surface Treatment

- Polished / Pickled

- Alloy or Not

- Non-Alloy / Alloy available

- Standard

- ASTM, DIN, JIS, GB

- Grade

- 201, 202, 304, 316, 310

- Outer Diameter

- 1/4 inch - 24 inch

- Size

- Customized

- Length

- Single Random, Double Random, or Cut-to-Length

- Magnetism

- Non-magnetic (Specific Grades)

- Pipe Weight

- Varies by Size and Thickness

- Weldability

- Excellent

- Temperature Resistance

- Up to 870°C

- Packaging

- Standard Export Packing or as Required

- MOQ

- Negotiable

- Rust Proof

- Yes

SS PIPES Trade Information

- Minimum Order Quantity

- 2 Kilograms

- Supply Ability

- 1000 Kilograms Per Month

- Delivery Time

- 7 Days

About SS PIPES

Versatile Usage & Distinctive Features of SS Pipes

Our stainless steel pipes are designed for a broad range of applications, including construction, plumbing, food processing, and industrial use. Featuring exceptional weldability, rust-proof surfaces, and durable round shapes, these pipes are manufactured using cold rolled technology. The machine's features ensure precise dimensions with a tolerance of 1%, while polished or pickled surfaces add to their functionality and appearance. End-protected with plastic caps, these pipes embody soaring reliability and long-term performance.

Streamlined Delivery and Exchange Processes for SS Pipes

Shipped goods are processed efficiently, ensuring timely delivery whether as single random, double random, or cut-to-length pipes. Our shipment operations are centered at key FOB ports across India, with flexible payment terms like T/T or L/C to facilitate smooth transactions. Exchange and export procedures are tailored to meet client requirements, ensuring that every shipment arrives as expected, whether packaged in standard export packaging or as specifically requested by the customer.

FAQ's of SS PIPES:

Q: How do I determine the right SS pipe size and thickness for my project?

A: To determine the most suitable size and thickness, assess your specific application-considering factors like pressure, temperature, and required strength. Our experts can guide you based on the intended use and industry standards.Q: What is the process for customizing the length and surface finish of SS pipes?

A: You can specify the desired length, whether single random, double random, or cut-to-length, and choose between polished or pickled surface treatments. Our manufacturing process is flexible to accommodate these preferences for every order.Q: When can I expect delivery after placing an advance purchase order?

A: Delivery time typically varies based on order size and customization, but we strive for prompt processing. Details on shipment timeline will be specified during the order confirmation.Q: Where are your SS pipes shipped from and what are the available FOB ports?

A: Our SS pipes are shipped from India, with major FOB ports available, depending on your location and shipment requirements. Information about the specific port used will be shared during the order process.Q: What are the benefits of choosing your SS pipes for industrial and construction projects?

A: Our SS pipes offer soaring durability, high-temperature resistance up to 870C, non-magnetic options, and excellent corrosion resistance. Their versatility and robust construction make them ideal for harsh industrial environments and demanding construction applications.Q: How does the excellent weldability feature enhance SS pipe usage?

A: Excellent weldability ensures seamless installation and integration in various systems, reducing installation time and cost, and guaranteeing strong, leak-proof joints.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Steel Tubes Category

M.S. Seamless Tubes

Price 68 INR / Kilograms

Minimum Order Quantity : 2 Kilograms

Standard : Other, ASTM, DIN, JIS, EN

Feature : High Strength, Corrosion Resistant, Durable

Application : Other, Automobile, Construction, Engineering, Gas Handling, Industrial

Technique : Hot Rolled

M.S Pipe Surplus

Price 65 INR / Kilograms

Minimum Order Quantity : 2 Kilograms

Standard : Other, ASTM, IS, BS

Feature : Corrosion Resistance, Durable, High Strength

Application : Other, Construction, Structural, Industrial, Plumbing, Fencing

Technique : Hot Rolled

Hydraulic Tubes

Minimum Order Quantity : 2 Pieces

Standard : Other, DIN 2391, EN 103054, ASTM A106, JIS G3445

Feature : Corrosion Resistant, High Pressure Capability

Application : Other, Hydraulic and Pneumatic Applications

Technique : Other, Cold Drawn / Seamless

Cylinder Tubes

Minimum Order Quantity : 2 Pieces

Standard : Other, DIN2391, EN10305, ASTM A519

Feature : Corrosion Resistant

Application : Other, Hydraulic Cylinders

Technique : Cold Drawn

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free